The relentless travel for greater energy density and effectiveness in modern-day electronics areas huge thermal strain on critical elements. Insulated Gate Bipolar Transistors, or IGBT modules, are workhorses in electricity conversion techniques, electrical vehicles, renewable Electrical power inverters, and industrial drives. even so, their capacity to take care of considerable electricity includes a major byproduct: warmth. efficiently managing this heat is not just useful; it is absolutely important for making certain effectiveness, trustworthiness, and longevity. when numerous cooling techniques exist, personalized liquid chilly plates have emerged given that the definitive Answer for tackling the demanding thermal difficulties posed by IGBT modules. Tailored to meet particular design and style and overall performance needs, these tailored answers ensure exceptional warmth dissipation while retaining procedure efficiency. this informative article delves into why liquid cooling, significantly options offered by specialists like Renxin Precision, signifies the head of thermal administration for these very important parts.

Table of contents:

The Unseen menace: comprehension the Thermal obstacle of IGBT Modules

Demystifying the technological innovation: what's a Liquid Cold Plate and How Does It function?

the proper Match: Why Liquid chilly Plates are perfect for IGBT Modules

The Renxin Precision benefit: Performance Rewards Embodied

Beyond Off-the-Shelf: Customization helps make the real difference

A Clear Winner: Comparing Liquid chilly Plates with regular Cooling

growing Horizons: Applications further than IGBT the place Liquid Cold Plates Shine

The Unseen danger: comprehending the Thermal Challenge of IGBT Modules

IGBT modules swap substantial currents at higher voltages, generating warmth from conduction and switching losses. As manufacturers purpose for scaled-down measurements and better ability output, ability density will increase, producing hotspots. These hotspots can quickly exceed Secure temperatures Otherwise managed properly.

the implications of inadequate cooling are severe. Elevated temperatures can cause:

decreased Efficiency: IGBT overall performance degrades as temperatures increase, bringing about higher Strength losses.

Decreased dependability: Thermal stress accelerates material exhaustion and degradation within the module, rising the chance of premature failure.

Shortened Lifespan: constant operation at higher temperatures considerably lessens the operational life span on the IGBT.

Parameter Drift: critical electrical properties from the IGBT can adjust with temperature, possibly disrupting procedure stability.

Catastrophic Failure: In Extraordinary instances, thermal runaway can come about, resulting in quick and infrequently damaging failure from the module and perhaps harming surrounding elements.

This inherent IGBT cooling problem underscores the necessity for State-of-the-art thermal administration in electronics. just attaching a standard heatsink is often inadequate for contemporary, significant-power IGBT programs. A more robust and productive cooling approach is necessary, foremost us straight to the notion of liquid cold plates.

Demystifying the technological know-how: what exactly is a Liquid Cold Plate and How Does It function?

A liquid chilly plate (LCP) is definitely an active thermal administration product intended to successfully transfer warmth from the heat-building ingredient, like an IGBT module, to the liquid coolant. Its standard composition commonly includes:

Base Plate: A thermally conductive plate, often comprised of copper or aluminum, that makes immediate contact with the warmth resource (the IGBT module). Flatness and area complete are essential for reducing thermal resistance at this interface.

inside Channels or Embedded Tubing: Pathways in the base plate that permit liquid coolant to flow. These may be machined, made by brazing layers, or produced by embedding tubes (like copper cooling channels) into the framework. Renxin Precision often utilizes large-conductivity copper tubing embedded in the base for exceptional heat transfer.

Inlet and Outlet Ports: Connection factors to the coolant loop, letting fluid to enter the cold plate, absorb warmth, and exit.

The Doing work principle is classy and productive:

one.Conduction: Heat created by the IGBT module is carried out into The bottom plate from the liquid chilly plate.

2.Convection (inner): because the coolant flows via the internal channels or tubes, it absorbs warmth in the surrounding plate substance by way of compelled convection. This is considerably more productive at removing warmth than the normal convection relied on custom liquid cold plates by uncomplicated heatsinks.

3.Transport: The heated coolant exits the chilly plate and circulates through a cooling loop, ordinarily like a pump and a heat exchanger (just like a radiator), the place the absorbed warmth is rejected into your ambient surroundings or Yet another cooling medium.

four.Recirculation: The cooled liquid then returns to the cold plate inlet to repeat the cycle.

in comparison to common air cooling (passive heatsinks or admirer-cooled heatsinks), liquid cold plates supply substantially better heat transfer coefficients. This top-quality cooling technology permits the dissipation of much bigger amounts of heat from scaled-down area locations, producing them indispensable for high-power density purposes.

The Perfect Match: Why Liquid chilly Plates Are Ideal for IGBT Modules

the precise qualities of IGBT modules make liquid chilly plates a particularly ideal cooling solution for numerous important causes:

Handling large Power Density: IGBTs deliver important heat in smaller deals, earning air cooling inadequate for that large heat flux regular of modern IGBTs. Liquid cooling gives significantly greater warmth absorption and transportation potential, straight addressing the primary IGBT module cooling obstacle.

Precision Thermal Management: Liquid chilly plates may be intended with optimized inside channels to target regions of greatest heat technology inside the IGBT module. This "spot cooling" is way simpler than normal air cooling, guaranteeing significant regions continue to be within Protected temperature limits.

Temperature Stability and Longevity: Liquid cooling keeps the IGBT module at decreased, much more steady temperatures, even beneath various loads. This security minimizes thermal pressure, extending the module's lifespan and trustworthiness—important for programs like renewable Electricity or automotive units. LCPs offer the higher-ability thermal Alternative desired for durable general performance.

The Renxin Precision benefit: overall performance Rewards Embodied

when the idea of liquid cold plates is impressive, the particular overall performance heavily will depend on design and style, products, and producing high quality. This is when Renxin Precision distinguishes alone:

outstanding supplies: Renxin utilizes high-purity copper for essential components like cooling tubes and sometimes the base plate. With great thermal conductivity (all over 400 W/m·K), copper ensures rapid heat transfer through the IGBT interface on the coolant. This substance option is the muse of a large-quality liquid cold plate.

Precision Manufacturing: Superior CNC machining assures limited tolerances, excellent surface flatness for exceptional thermal contact with the IGBT, and reliable internal stream channels. This assures reliable thermal efficiency and fluid dynamics within the copper cooling plate. The product or service (Φ80.31x3901335x L6852697) showcases specific Proportions customized for precise IGBT modules.

Increased sturdiness: Renxin cold plates are built for sturdiness. High-quality components and strong design resist corrosion, function with popular coolants (like water-glycol), and accomplish nicely in difficult industrial environments.

Choosing Renxin Precision usually means choosing a liquid cold plate engineered for max thermal general performance, reliability, and longevity, immediately translating to enhanced IGBT module Procedure.

further than Off-the-Shelf: Customization tends to make the Difference

Recognizing that thermal difficulties are distinctive to every application, Renxin Precision locations a solid emphasis on customization. normal answers might not constantly deliver the best in good shape or efficiency. A personalized liquid chilly plate solution presents major strengths:

customized structure: Renxin works with purchasers to layout cold plates that meet up with distinct desires. This consists of custom made dimensions to fit restricted Areas, optimized internal channels (e.g., serpentine, parallel) for focused cooling, and precise inlet/outlet ports for seamless procedure integration.

program overall flexibility: Custom and modular designs give engineers more liberty in method architecture. From compact electrical power enclosures to big industrial cabinets, personalized liquid chilly plates may be tailored to suit any require.

numerous field Support: As a qualified OEM cold plate provider, Renxin Precision offers OEM/ODM services to develop bespoke thermal options for a variety of sectors. Renxin custom made answers empower innovation by removing thermal limitations and meeting efficiency, Price, and integration needs.

This capability to tailor the solution makes certain that the liquid chilly plate performs optimally for the specific IGBT module and running conditions, maximizing effectiveness and trustworthiness.

a transparent Winner: Comparing Liquid chilly Plates with classic Cooling

When evaluating cooling choices for demanding apps like IGBT modules, a immediate comparison highlights the superiority of liquid chilly plates:

Liquid vs. Air Cooling (Heatsinks/lovers):

oPerformance: Liquid cooling features noticeably increased heat dissipation capability per unit quantity. Air cooling turns into impractically massive and noisy for prime heat loads the place liquid cooling remains compact and efficient.

oTemperature Gradient: Liquid cooling commonly achieves lessen component temperatures and improved temperature uniformity over the module.

oEnvironment: Liquid cooling effectiveness is fewer impacted by large ambient air temperatures compared to air cooling.

Liquid Cooling vs. Heat Pipes:

oCapacity: even though warmth pipes are outstanding at spreading warmth, they typically trust in an air-cooled fin stack for supreme dissipation. Liquid chilly plates integrate the heat absorption and transport features a lot more instantly and customarily provide greater whole heat elimination ability.

oTransport length: Liquid cooling can transportation heat around much longer distances (to some remote warmth exchanger) far more properly than heat pipes.

when standard strategies like air cooling have their spot for reduced electrical power applications, the thermal efficiency comparison Obviously favors liquid cooling in significant-heat-flux environments or where Place is limited. Even though the First procedure Expense for liquid cooling may be larger, the Return on financial investment (ROI) Investigation generally favors LCPs due to:

Enabling larger electrical power density (more energy in significantly less House).

Improved procedure reliability and lowered downtime.

prolonged part lifespan.

probable for quieter system operation.

diminished In general method dimension sometimes.

For demanding IGBT apps, the advantages of liquid vs air cooling overwhelmingly point toward liquid methods.

Expanding Horizons: Applications further than IGBT in which Liquid Cold Plates Shine

The efficiency of liquid cold plates extends much past just IGBT modules. Their capability to regulate significant warmth hundreds in compact sorts can make them perfect for an array of demanding apps:

Electric auto (EV) methods: Cooling batteries, traction inverters (which frequently use IGBTs or similar energy modules), onboard chargers, and higher-electricity DC quick charging infrastructure (EV thermal management).

details facilities and Servers: Cooling high-efficiency CPUs, GPUs, and also other densely packed server components.

Telecommunications: running heat in energy amplifiers, base station equipment, and also other essential telecom cooling situations.

Renewable Vitality: Cooling substantial inverters Employed in photo voltaic farms and wind turbines.

healthcare devices: Thermal administration for clinical lasers, MRI programs, CT scanners, and diagnostic gear necessitating steady temperatures.

Industrial methods: Cooling superior-power lasers, welding devices, industrial electric power provides, and variable frequency drives.

The frequent denominator throughout these numerous liquid chilly plate programs is the need for economical, reputable, and often compact thermal administration solutions effective at dealing with important warmth hundreds.

The thermal requires of modern IGBT modules demand a cooling Alternative that is certainly equally highly effective and exact. Liquid cold plates satisfy this will need with exceptional warmth dissipation, qualified thermal management, and enhanced temperature stability compared to standard methods. They may be significantly the ultimate Alternative for unlocking the complete potential of IGBT know-how although ensuring very long-term trustworthiness.When choosing a liquid chilly plate, factors like content quality, producing precision, and customization selections are vital. Renxin Precision stands out as a number one supplier, offering high-overall performance copper chilly plates designed for demanding applications. Their CNC machining, higher-conductivity elements, and custom methods make them a really perfect thermal management partner.when you’re tackling IGBT cooling challenges or creating techniques that will need best-tier thermal administration, Checking out Renxin Precision’s liquid chilly plates is essential. lover with them to satisfy your thermal requirements and enhance your power electronics. Get in touch with their engineering group right now to debate your demands and learn how their remedies can reward your undertaking.

Michelle Pfeiffer Then & Now!

Michelle Pfeiffer Then & Now! Molly Ringwald Then & Now!

Molly Ringwald Then & Now! Elisabeth Shue Then & Now!

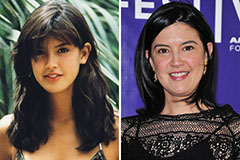

Elisabeth Shue Then & Now! Phoebe Cates Then & Now!

Phoebe Cates Then & Now! Raquel Welch Then & Now!

Raquel Welch Then & Now!